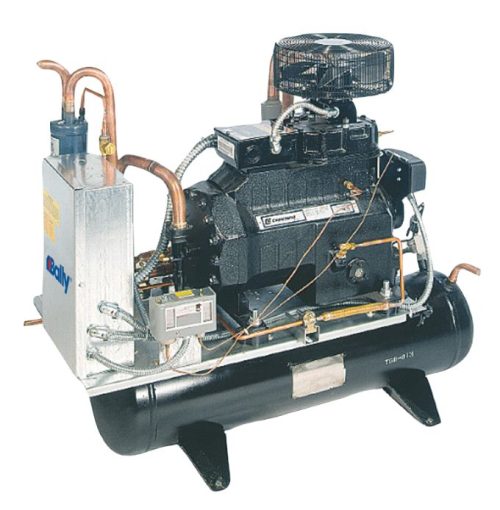

BC Combination Condensing Units

October 22, 2018

BM – Medium Outdoor Air Cooled Condensing Units

July 21, 2016BV – Large Outdoor Air Cooled Condensing Units

CONTACT A PRODUCT SPECIALIST TODAY:

See our Product Data and Specifications (Copeland Compressor Models)

See our Product Data and Specifications (Bitzer Compressor Models)

Our BVS/BVD condensing units meet or exceed the new “AWEF” requirements for condensing units. Use this guide which collects all of the AWEF numbers for compliant equipment: https://docs.b-rp.ca/awef/br_awef_quick_reference.pdf

Have questions about AWEF, WICF, etc.? Visit our AWEF-FAQ

Certification:

Features:

- Compatible with Low GWP Refrigerants

- Units are CULUS Listed

- Designed for use with various popular refrigerants

- Energy efficient compressors with POE or mineral oil

- Several compressor options to choose from: Copeland Discus and Bitzer reciprocating

- Single, Dual and parallel-piped (optional) compressor configurations available

- ThermospanTM condenser core design eliminates tube sheet leaks and provides reliable operation

- 3/8″ condenser tubes reduce refrigerant charge

- Generously sized condenser allows unit to operate at higher-than-normal ambient conditions

- Optional coating and fin surfaces for condenser core protection available

- Specially designed, thermally protected and permanently lubricated ball bearing condenser fan motor(s)

- Receivers (where used) are liberally sized and include inlet as well as outlet service valves

- Subcooling circuit in condenser on all models (except on H8 models) increases overall system efficiency and provides dependable compressor operation

- Utilizes pre-formed internal piping, eliminates welded joints and reduces chances of a leak

- Electrical components are housed in a spacious and conveniently located panel. In case of a compressor trip, (except on air conditioning models) a lock-out relay de-energizes the liquid line solenoid valve. In addition, SPDT contact is provided for field-wired alarm circuit

- End compartment panels allow unrestricted access to service the compressor(s) and all other components.

- Raceway for pressure control wiring and connections provides neat appearance.

- Units are available with energy-efficient ThermosaverTM hot gas defrost option

- Units are environmentally friendly operating on less power and refrigerant charge

Standard features include:

- Spring mount compressor with discharge vibration eliminator

- Compressor head cooling fans on low-temperature models (except L8 units)

- Compressor crankcase heater

- Flexible hose on all compressor pressure control connections

- Two valve adjustable (pre-set at factory) low ambient head pressure control

- Condenser fan cycling control (pressure) on two-fan models and up

- Fused condenser fan motors

- Receiver inlet/outlet valves and safety pressure relief valve

- Replaceable liquid line drier & sight glass

- Anti-short cycle time delay relay

- Oil failure control (non-electronic)

- Separate HP and LP compressor controls

- Part-winding start on all 30 HP and up, operating on 208/230V-3Ph.

- Lockout relay

- Sub-cooling circuit on medium and low temperature units

- Electronic liquid injection on L8 units

- Suction line vibration eliminator

Available Options:

- NEW Pre-Selected Factory Mounted Options Packages

- Limitrol+ Head Pressure Control System

- Suction accumulator (with or without heat exchanger)

- Replaceable suction filter

- Insulated suction lines

- Crankcase Pressure Regulating valve

- Compressor capacity control (cylinder unloading on 4D-6D-6F compressors or ModuloadTM on 3D compressor)

- Discharge line check valve

- Hot gas bypass tees / regulating valves / de-superheating TXV

- Oil separator

- Oversized condenser

- Oversized receiver

- Heated and insulated receiver

- ThermosaverTM defrost

- Disconnect switch (fused or non-fused)

- Compressor circuit breaker

- Electronic Oil failure control

- Voltage / Phase monitor

- Part-winding start (standard on 30HP and up operating on 208/230-3)

- Defrost Time clock

- Defrost Heater / Evaporator Fan Contactors with fuse block

- Single point electrical service hook up for evaporator and controls

- Variable speed EC motors only as head pressure control

Application:

- High, medium and low temperature applications.

- Dual or Single Compressor

Capacity:

- Nominal Capacities from 10 to 100 Tons for high, medium and low temperature applications

Electrical:

- 208-230/3/60

- 460/3/60

- 575/3/60

- 200-220/3/50

- 380-400/3/50

Product Manuals & Specifications:

Product Data and Specifications (Copeland Compressor Models)

Product Data and Specifications (Bitzer Compressor Models)

Installation Manual

Limitrol+ Application Guide

Head Pressure Control Application Guide

Related Sales Material:

All-Product Brochure

Limitrol+ Floating Head Pressure Control System Sell Sheet

Shafted EC Motors Sell Sheet

Additional Links:

About Heated And Insulated Receivers

Evaporator Defrost Kit and Fuse Package Selector

Shafted EC Motors

About Limitrol+

ThermoSaver Hot Gas Defrost System

Download AutoCAD Drawings

Download High-Resolution Image

AWEF-FAQ

AWEF numbers for Bally Refrigeration AWEF-compliant condensing units

Service Parts:

Search for BVS Parts In The Service Parts Database

Search for BVD Parts In The Service Parts Database

Email Our Service Parts Specialists

Product Specialist:

[email protected]

1-844-893-3222 ext. 522